Version with parts in contact with the product in "Food Grade"

The Tubular Chain Conveyor is a mechanical system used to transport bulk materials like agri-food products, pet food, animal feed, pellets, and TPE.

What is the Tube Chain Conveyor?

The tubular chain conveyor can transport large quantities of material over long distances, safely and efficiently.

It is suitable for conveying all sorts of granular, powdery, friable, and delicate products such as powders, chemicals, plastic granules, TPE, pet food, animal feed and agri-food products.

How does a Tubular Conveyor work?

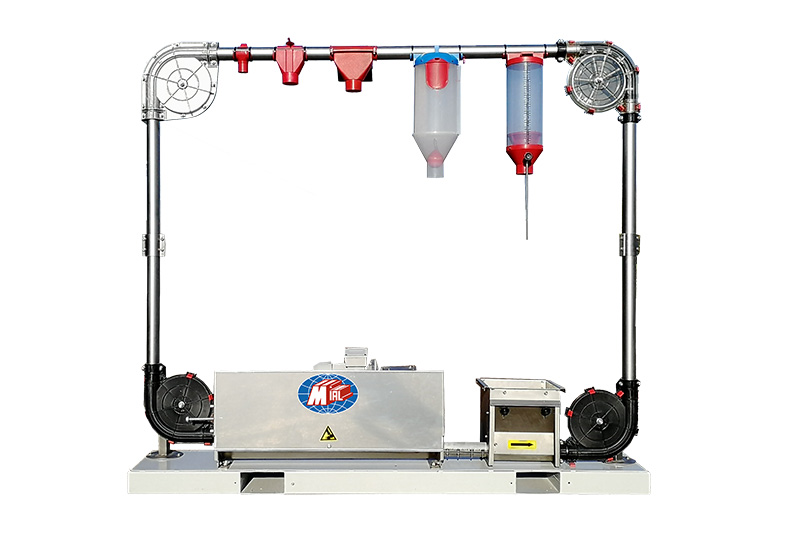

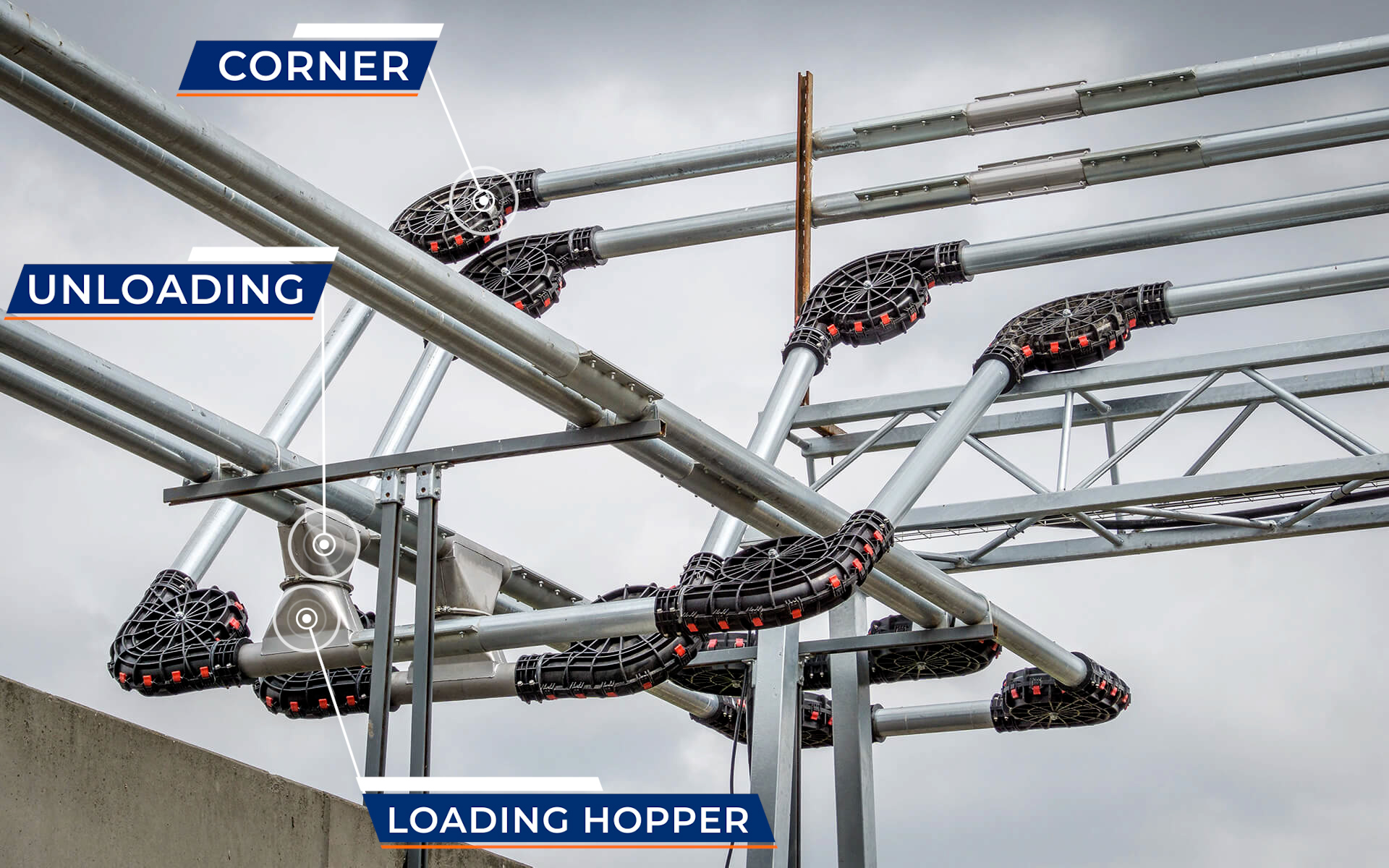

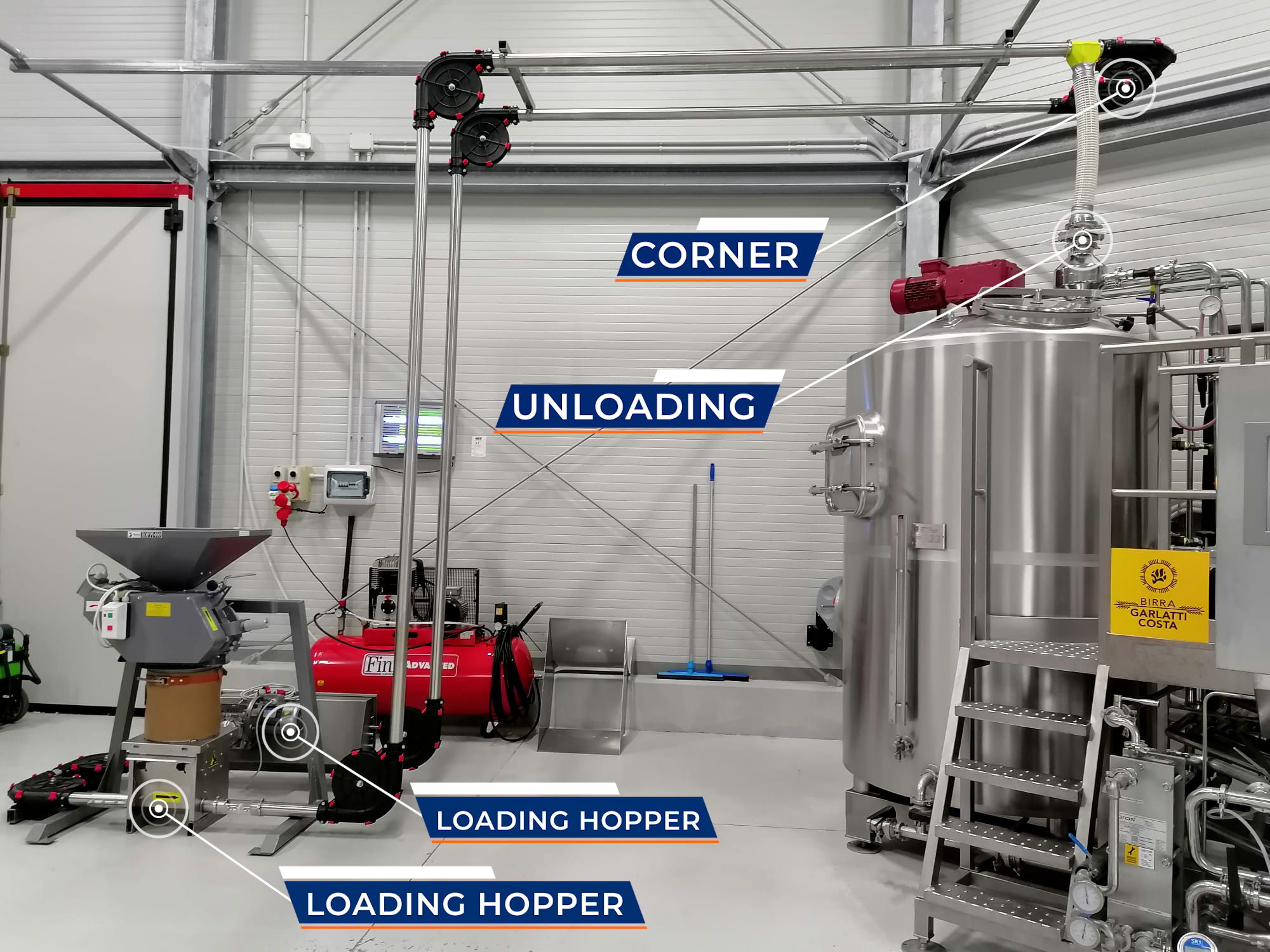

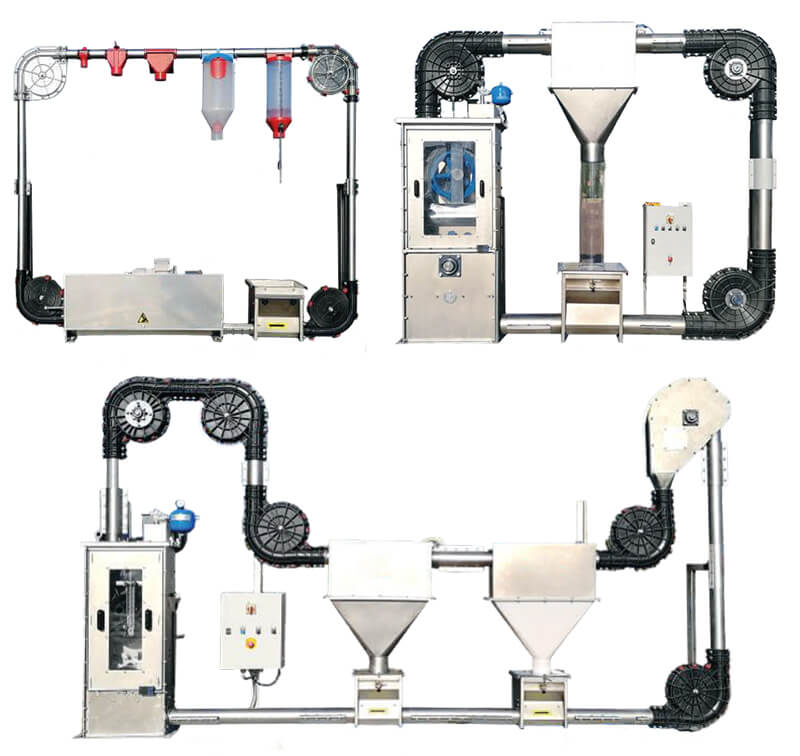

Tubular conveyors are made up of tubes, curves/corners, and loading and unloading hoppers.

1- Product is fed into the tubes through the loading hopper

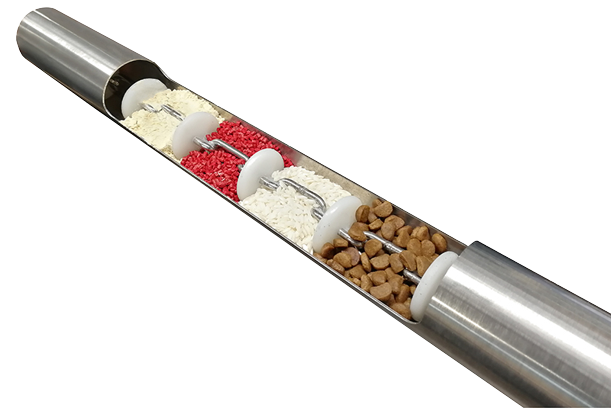

2- The product is dragged inside by chains equipped with curved discs made of plastic.

The diameter of these discs varies according to product specifications and customer needs.

3- Finally, discharge products are released from stainless steel hoppers with shutter valves that open or close the tube to increase or decrease the amount of product falling

These are our solutions:

Ideal for Malt, Cereals, Animal feed, Plastic materials

Ideal for Seeds, Pet food, Cereals, Granular products

Ideal for Coffee beans, Bulk ingredients, Grains, Wooden pellets

.png)

These are the benefits of choosing Tubular Chain Conveyor:

Section of the system installed in China

Section of the system installed at BIRRA GARLATTI

Read the article below and learn about one of the largest chain conveying systems designed and installed.

Request information

Request information  Download pdf

Download pdf

There are many reasons to choose our products

Ask for a quotation, and we will contact you on a working or non-working day.

Discover more

Discover more

Customised plant for pet food production and greasing. Conveying, dosing, mixing and cooling systems

Read more