Control Panel

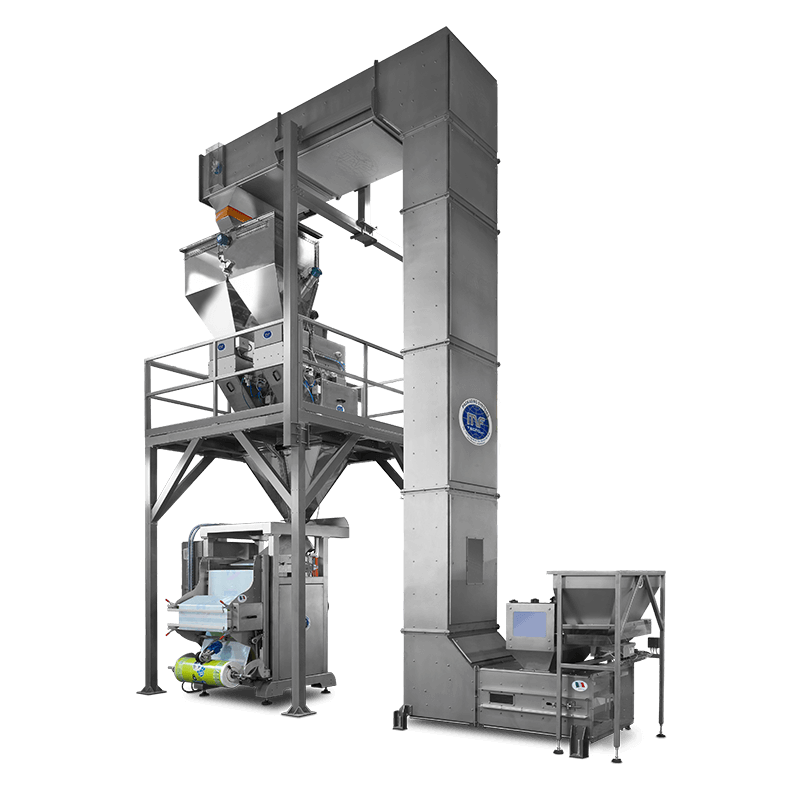

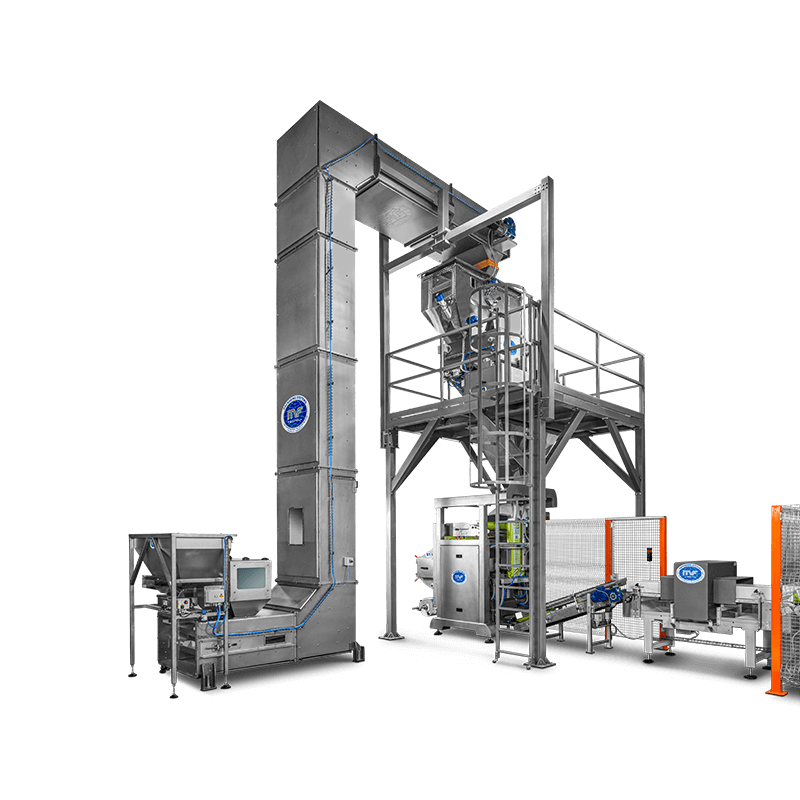

The Pendulum Bucket Elevator is the ideal solution for conveying fragile and delicate granular products, whose integrity must be preserved.

MIAL's Bucket Elevators incorporate vertical and horizontal transportation of bulk materials in one integral unit, offering a safe, fast and cost-effective way to move large quantities of bulk materials.

Our bucket elevators are designed for the gentle handling and transport of a broad range of bulk products, including fragile and non-fragile items in the food, agriculture, pharmaceutical, cosmetic, chemical industries.

MIAL Bucket Elevators are known for the many advantages they offer:

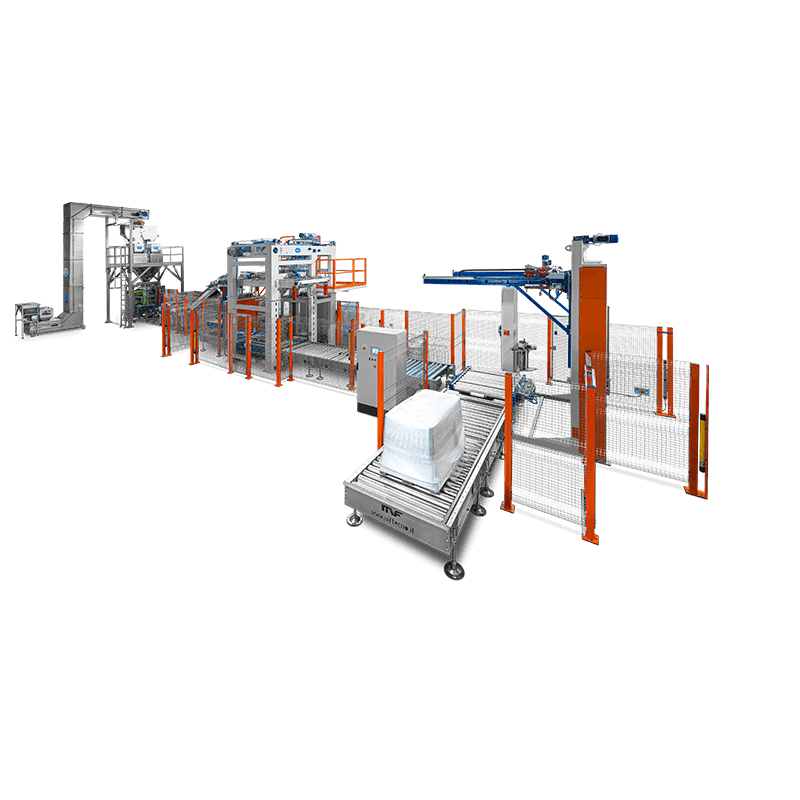

MF TECNO develops customized solutions, combining speed and quality.

Thanks to high flexibility and continuous R&D activity, our systems are suitable for a lot of applications. Some examples are: pasta, biscuits, deep-frozen products, pet food, chips, rice and seed.

.png)

The continuous handling of the product, which is introduced into the loading hopper, is done by a series of oscillating buckets by means of a vibrating feeder.

The buckets are fixed equidistantly along a chain. Maintaining a horizontal position and overlapping the edges of the cups in the inlet section prevents product loss.

Each cup is then tilted and the product, which falls by force of gravity, is gently guided into the outlet hopper. This prevents it from being damaged during discharge. It guarantees maximum respect for the integrity of the transported product.

In the videos below you can see 2 Oscillating Bucket Elevators in action, entirely designed and produced by MIAL.

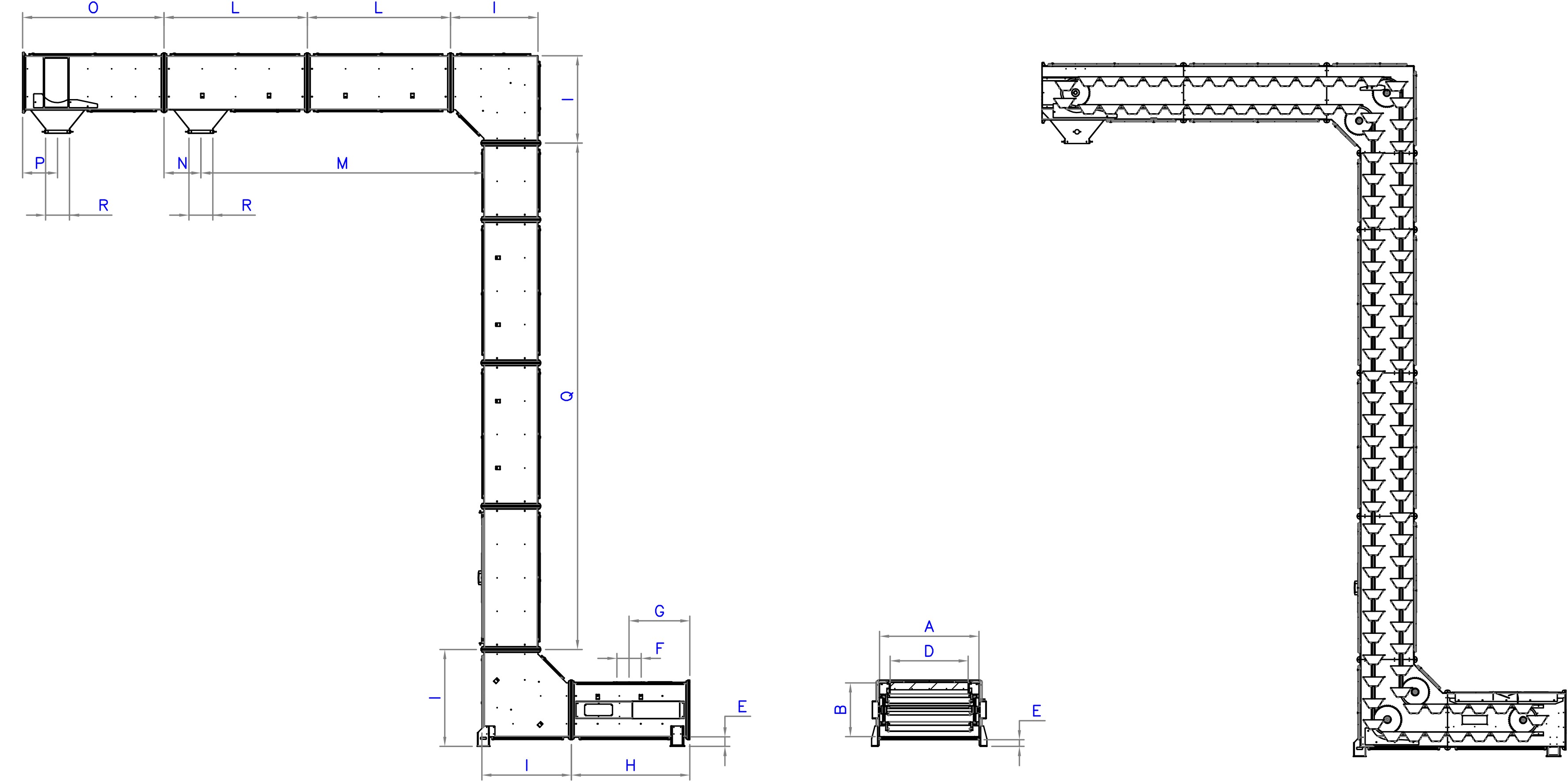

Our Bucket Elevators are available in 5 sizes: from 72 to 248 cubic meters/hour.

MIAL Bucket elevators can be built in a variety of configurations, including Z-shape and C-shape.

Z-shape is the most common configuration.

Oscillating buckets are one of the key elements of our elevators.

Buckets made of Stainless steel with PE / Polyethylene-Polyzene sides:

In the VIDEO below you can see two Oscillating Bucket Elevators in action, entirely design and produced by MIAL.

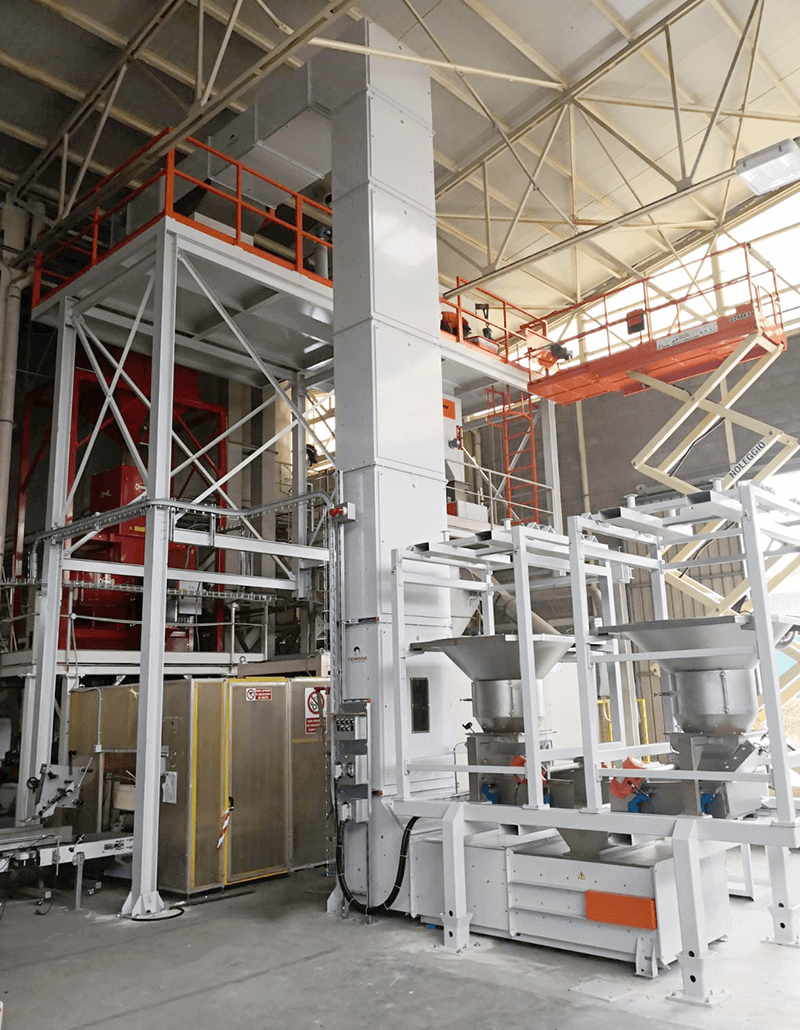

The first elevator is for GINOR company (Tunisia), a customer needing to elevate sugar.

The second elevator is for Propack kft company (Hungary), a customer needing to elevate Pet Food.

Request information

Request information

There are many reasons to choose our products

Ask for a quotation, and we will contact you on a working or non-working day.

Discover more

Discover more

Customised plant for pet food production and greasing. Conveying, dosing, mixing and cooling systems

Read more