What is Coating processing with a Vacuum Mixer?

Coating with a vacuum mixer is a processing technique used to add high percentages of liquid additives to extruded products.

It allows the producers of Pet Food and Fish Food to improve the quality and nutritional capacity of the product.

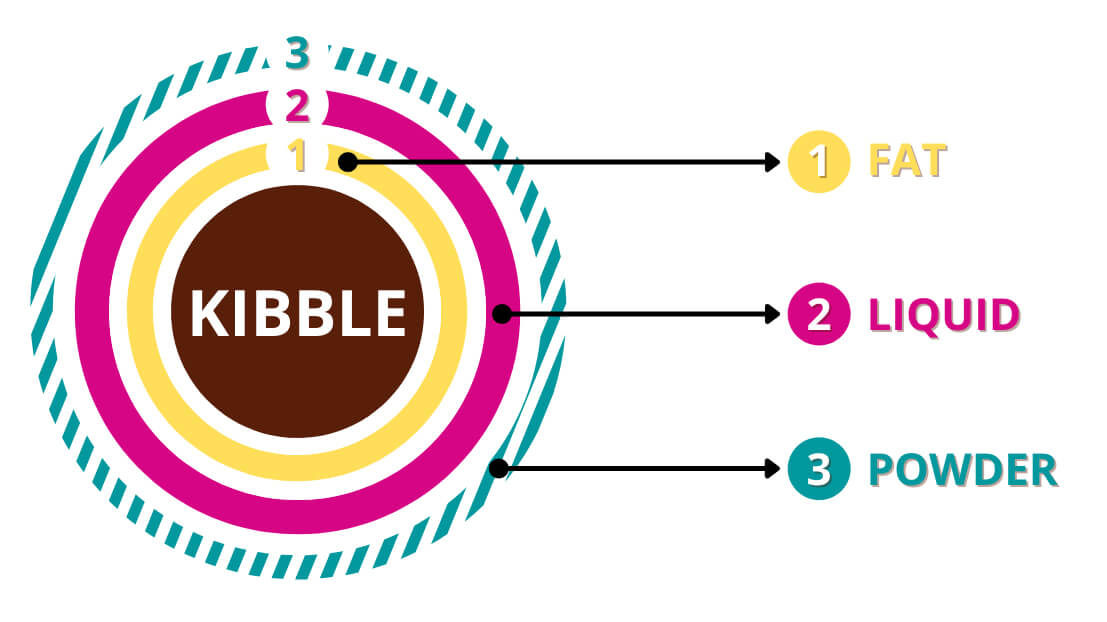

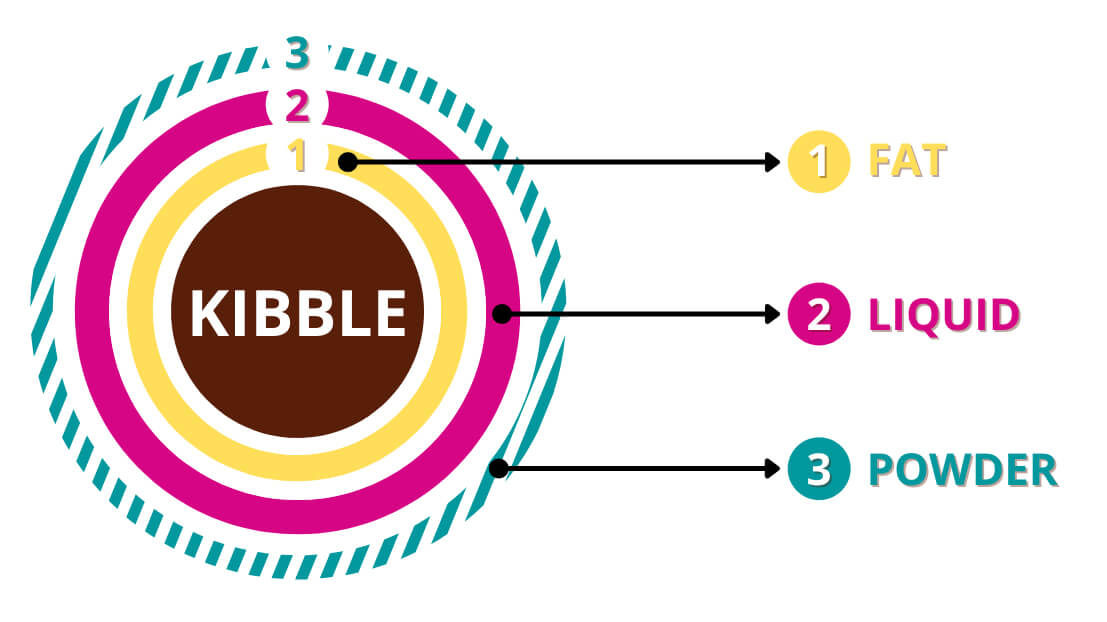

This is done by adding functional additives such as fats, oils, water-based additives (e.g. appetizing substances and antioxidants) and powdered additives.

Using the coating technology with a vacuum mixer, the oily additives penetrate evenly and deeper inside the kibble.

This results in higher quality and more nutritious Pet Food and Fish Food, consequently in healthier animals because they are fed correctly.

This process has another advantage: protecting the kibbles from possible crumbling.

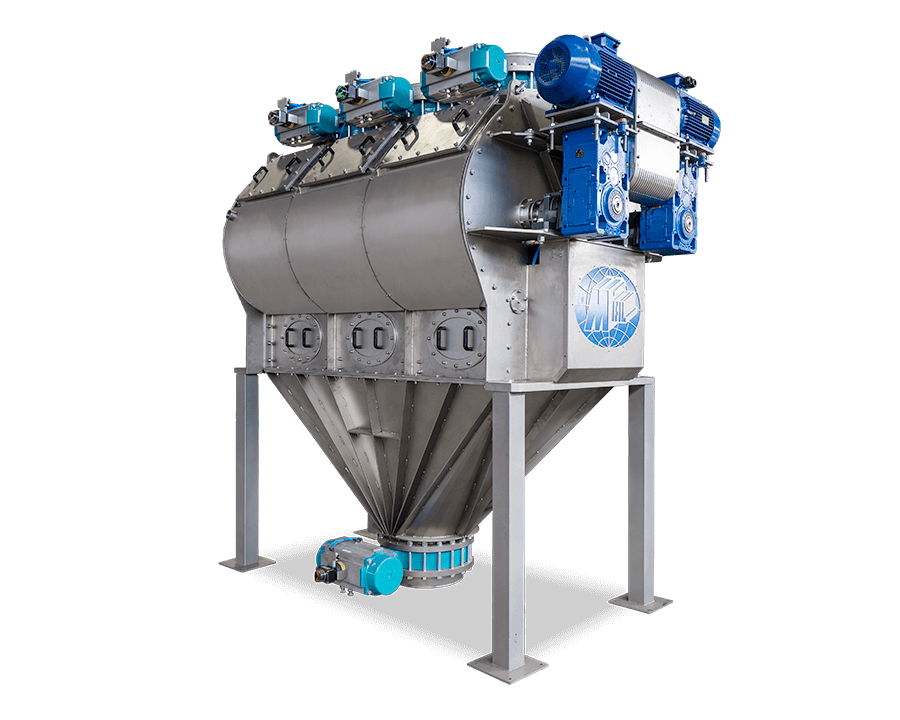

How does MIAL Mixer/Coater work?

In the picture below it is possible to figure out how the mixer works.

- The product is dosed in special weighing hoppers.

- The product enters the MIAL Mixer/Coater. Then a vacuum environment is created in the mixing unit and the products, thanks to their porosity, are deprived of the air inside them.

- The use of a vacuum environment ensures that the additives penetrate in depth into the kibble.

- While the vacuum is maintained inside the machine, predetermined quantities of liquid additives such as fats and oils are sprayed. Water-based and powder-based additives can also be added at a later stage, but in the same treatment cycle.

- When the inside of the machine returns to atmospheric pressure, the oily additives present on the surface of the kibbles are pushed into them by the air.

- After this step, additional layers of coating or flavorings are applied to each particle, which results in a high quality extruded product.

- Often an additional thin layer of fat is applied to the granular product. This layer makes the material tastier and more elastic, so that it breaks or crumbles less quickly.

The whole process takes place very quickly and takes only a few minutes.

Some more curiosity…

- The percentages of additives are extremely precise as the product before to be dosed is weighed alternately in one of the two hoppers. On the basis of the weight acquired, the quantities of additives to be added to the three scales are measured: one for oily liquids, one for liquids on aqueous base and one for powders.

- Thanks to the synchronized double shaft mixing technology, the process is extremely fast and precise and allows the user to obtain a very effective mixing, with a Coefficient of Variation <3%, in less than a minute from the addition of the last additive.

- The machine is produced in two models: 2.2 and 1.1 m3 of useful capacity.

In the video below you can discover the main components of the system.

Request information

Request information

Request information

Request information

Discover more

Discover more